How can we reduce our environmental impact and the spread of microplastics?

For sportswear in general and for technical running and trail running clothing or hiking (or also for cycling and swimming), polyester is one of the most commonly used fabrics. It is a strong material, resistant to creasing and above all it dries very quickly. Unlike cotton for example which absorbs water and is therefore hydrophilic, polyester is a hydrophobic fabric which does not absorb water and therefore sweat. On the contrary, it allows perspiration to dry naturally.

Polyamide is another synthetic fiber that is very common in the sports world. This fiber is very strong and durable. It resists wear and tear. It is an ideal fiber for sports activities that involve frequent movement and friction (such as with a trail bag or a backpack). Polyamide also offers elastic properties, which provide athletes with comfort and flexibility. It is also a fiber that can be used to make lightweight, breathable fabrics.

Polyester and polyamide are therefore widely used in the sports clothing industry for their technical characteristics which are particularly appreciated by athletes.

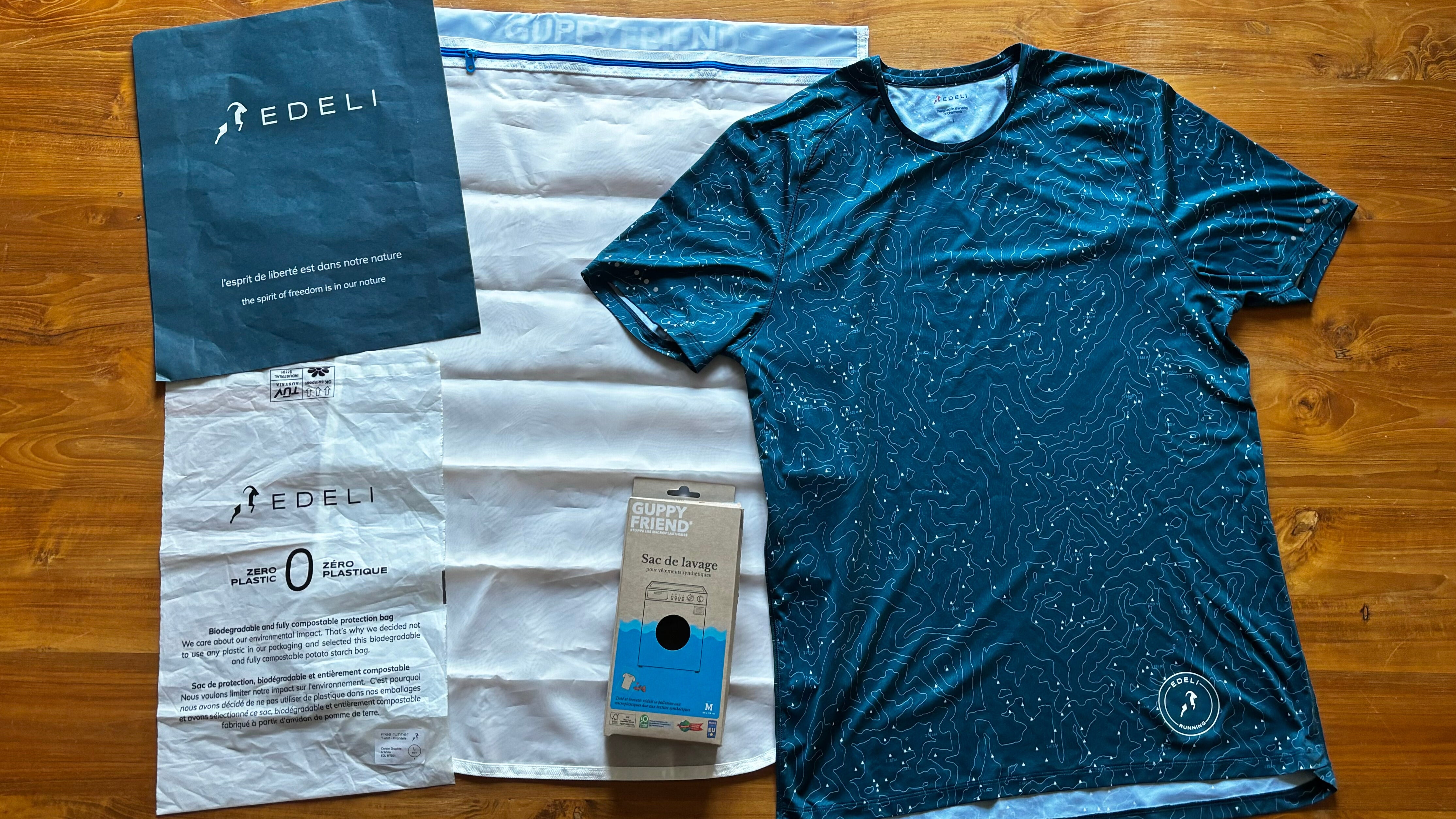

To limit the environmental impact of using these fibers and beyond all the stages of the life of a sports garment like those we design at EDELI (from manufacturing to storage then transport and finally during the life of the garment including washing cycles), there are several possible solutions and choices that we have made for EDELI in line with our commitment to creating an eco-responsible brand. Let's start with the washing stage before going further upstream on those of manufacturing and transport/storage.

Use a special washing bag to reduce the spread of microplastics

When washing at home, a key point is to ensure that the spread of microplastics is reduced. To do this, we recommend a simple and effective solution. It applies to all synthetic clothing washed at home or in a laundromat, not just sportswear but all clothing made from synthetic fibres. It simply involves using a washing bag specially designed to reduce the spread of microplastics during washing cycles. By inserting synthetic clothing into this large capacity washing bag (74 cm x 50 cm), the microplastics from synthetic textiles and microfibres are retained in the bag. At the end of the washing cycle, simply remove the clothing and then separately remove the microfibres trapped in the washing bag. This bag has a second advantage: it protects the clothing from friction in the washing machine drum.

The laundry bag we recommend is called Guppy Friend . It is made in Portugal from recycled fibers and costs around €30. It is available for purchase on the Nature & Découvertes website.

Apply antibacterial treatments to reduce washing frequency

Another solution to reduce the impact of washing, applicable to EDELI technical running and trail running clothing and very easy to implement, is to limit the number of washes. For all our technical running and trail running shorts and T-shirts, we apply a treatment based on silver ions, which have an antibacterial effect. In concrete terms, this means that this treatment limits body odours linked to perspiration caused during a sports session. For running sessions during the week, for example, of moderate duration (less than an hour for example), it is possible to wash the clothes only every two uses and not after each use without having any olfactory discomfort during the second session. Over the life of the garment, this can contribute to significantly limiting the total number of washes (and therefore reduce the consumption of water, laundry liquid, electricity, etc.).

Manufacturing clothing close to where it is sold to reduce carbon footprint

Let's now return to the clothing manufacturing stage. Manufacturing clothing in Europe to sell it in Europe allows us to significantly reduce the carbon footprint linked to the clothing production stage and to the transport stage. This is a commitment that we made for the EDELI brand since its creation. During the production stage, several sub-stages such as fabric manufacturing or treatments such as dyeing are particularly energy-intensive. However, a major difference between production in Asia and production in Europe is the greater share of fossil fuels and in particular coal in the energy mix in Asia compared to the energy mix in Europe. Since coal in particular and fossil fuels in general emit much more CO2, the carbon footprint per kilowatt/hour is much higher in Asia than in Europe. In addition to this difference linked to the production stage, there is also the difference linked to transport since intercontinental transport can simply be eliminated by producing clothing in Europe that is sold in Europe.

Designing clothing made from recycled fibers

Another solution to limit the environmental impact (and a choice we have made for all the EDELI technical running and trail running clothing we design) is to promote the use of recycled synthetic fibers. This helps contribute to a circular economy by giving a second life to products that have already been used (such as plastic bottles or used tires). For example, our SECOND SKIN technical running T-shirt from the FREE RUNNER range is made from 100% recycled fibers and our PERFECT FIT technical running shorts from the FREE RUNNER range are made from 88% recycled fibers.

Ban the use of plastic bags to protect clothes

To reduce the environmental impact during the transport and storage stages of sports clothing, a simple and radical solution exists, a solution that we have implemented at EDELI since day one. It consists of banning the use of plastic bags, called polybags . These are single-use plastic bags to protect clothing during transport and storage. At EDELI, we therefore decided from the creation of the brand to ban plastic bags in our packaging and opted for bags made from potato starch. They are completely biodegradable and compostable. They are less transparent than plastic bags but perfectly fulfill their role of protecting clothing during transport and storage.

Providing the technical performance that athletes are looking for in sportswear while limiting environmental impacts is not only possible, but we are convinced that it is necessary in a world subject to climate risks. In any case, this is our purpose: combining technicality and eco-responsibility to design ultra-comfortable and resolutely eco-responsible running and trail running clothing. To transform this purpose into concrete commitments, we are implementing several solutions such as manufacturing our clothing in Europe from recycled synthetic fibers, a zero-plastic policy in our packaging and the application of antibacterial treatments to limit odors linked to perspiration and thereby offer the possibility of reducing the frequency of washing. We also recommend using specially designed washing bags during washing to reduce the spread of microplastics. This shows that it is entirely possible to improve the environmental impact associated with technical running and trail running clothing that contributes to the pleasure that these sports give us. This is both our conviction and our reason for being, as running and trail running enthusiasts and as entrepreneurs committed to helping change things and having a positive impact on our industry and on the practice of our favorite sports.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.